Gearbox Overhaul by Experienced Service Technicians:

Our experienced service technicians and master craftsmen have built their knowledge in gearbox construction over decades. They combine this expertise with the technical office to ensure the high-quality overhaul of your drive.

Submitted gearboxes are opened, and damages are promptly assessed and documented. With the damage report, you will receive a quotation and, if necessary, improvement suggestions. Defective parts are either reconstructed and replaced through measurements or calculations. You will receive a gearbox in “like-new” condition.

Our Services Overview

- Disassembly: Professional dismantling of the gearbox.

- Inspection: Careful examination and evaluation of the condition.

- Damage Analysis: Analysis of identified damages to the gearbox.

- Reverse Engineering: Reconstruction of parts through reverse construction.

- Documentation: Comprehensive documentation of the entire process.

- Quotation: Preparation of a quotation based on the damage analysis.

- Restoration: Repair and restoration of the gearbox.

- Test Run: Conducting test runs to ensure functionality.Test Run: Conducting test runs to ensure functionality.

HUEBER Service GmbH repairs gearboxes of all brands, types, and models.

Under the “Gear Brands” menu, you will find an overview of the most common models. If your gearbox, whether standard or exotic, is experiencing issues, we are here as a competent service partner with expertise and years of experience.

We solve your problem quickly and reliably. Challenge us!

Industrial gearboxes with synchronous output shafts for repairs

The two output shafts had heavy wear on the journals; the required tolerances could no longer be maintained.

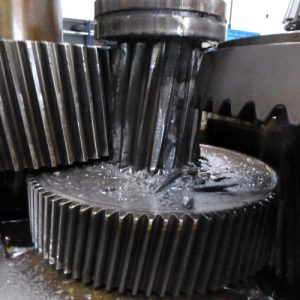

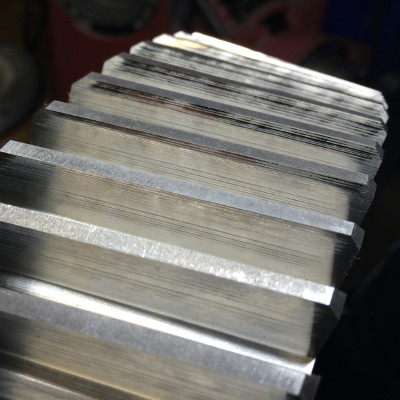

Gear wheel with heavy wear

Replacement of all roller bearings, the two output shafts and the pinion shaft. Assembly and adjustment of all bearing clearances, including the bottom-running bevel gear set with final test run and repainting. Due to the required parallelism of the two parallel keyways to each other, these had to be installed on the boring mill after assembly.

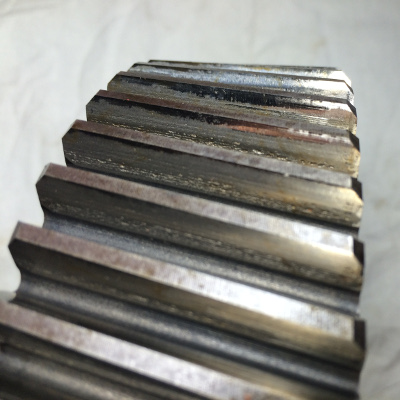

Gear wheel with heavy wear

Gear wheel with signs of wear, but still undamaged.

Industrial gearbox with co-rotating output shafts for repair

The two output shafts had heavy wear on the journals; the required tolerances could no longer be maintained.

Replacement of all roller bearings, the two output shafts and the pinion shaft. Assembly and adjustment of all bearing clearances, including the bottom-running bevel gear set with final test run and repainting. Due to the required parallelism of the two parallel keyways to each other, these had to be installed on the boring mill after assembly.

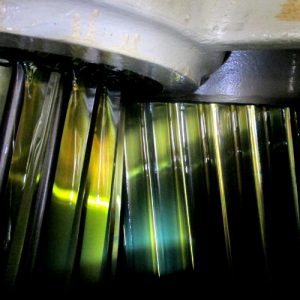

Repaired pulper gearbox from SEW

Recurring damage to lapped bevel gear teeth.

The gearbox is returned to the customer with a new, optimized HPG gear set and a new bevel pinion shaft.