With the new HUEBER GEAR XY, we can measure your gear components, whether heavily worn or partially destroyed, as unknown gear geometry. The measurable geometry is used to determine the gear geometry (helix angle, module, profile shift, backlash, or fillets). Your manufacturing data can be verified with the counterpart or based on the center distance, either at your location or in our workshop.

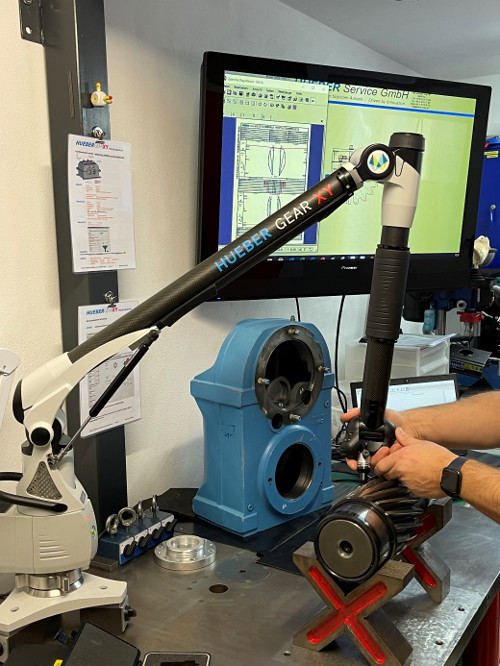

Measurement of an unloaded / good flank on a severely damaged gearing

Measurement of unknown gearing with HUEBER GEAR XY

With the new, unique service offering HUEBER GEAR XY, we can measure your gearings on-site (INHOUSE) or at our location at Altdorf and generate the geometry of your gearing for the production of new parts.

Our measurement technicians or engineers can come to your workshop promptly, i.e., immediately upon request, to take measurements of the gearing. If you can spare the parts, the gearing can also be measured after sending them to us. For older systems or gears, OEMs often no longer have verified data available, so they increasingly insist on sending in and checking the entire gearbox. Thus, the advantage of the OEM shifts to a cost disadvantage compared to the manufacturer-independent, professional gearbox repair by HUEBER Service.

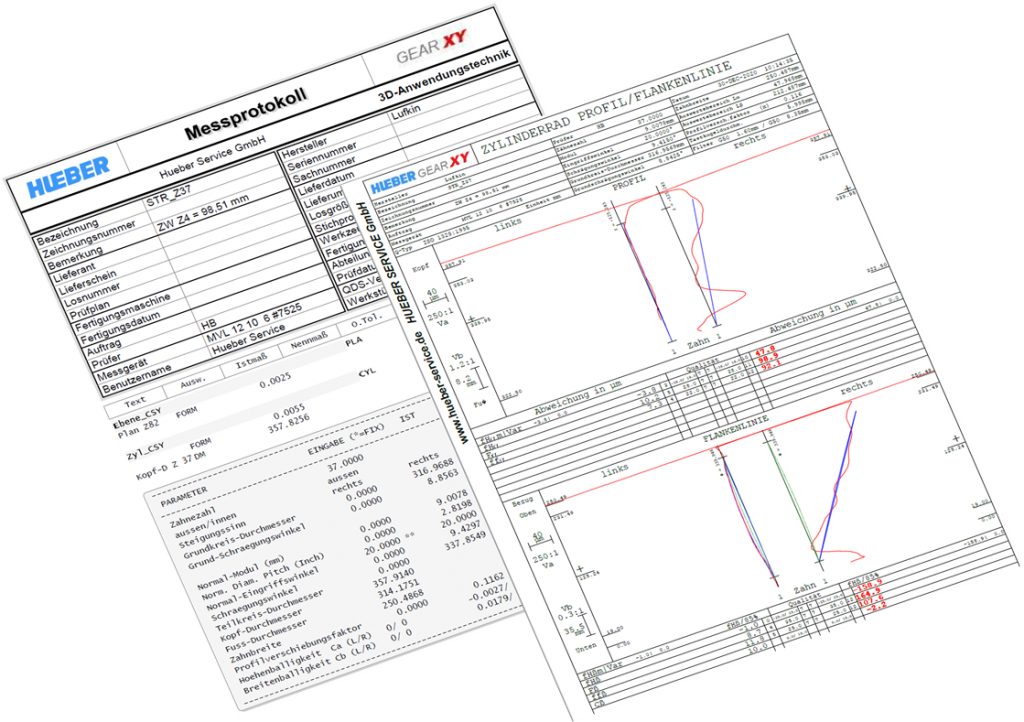

If teeth are still undamaged on at least one flank, HUEBER GEAR XY can capture the original gearing along with the existing corrections (convexities, profile shifts, etc.). Subsequently, the gearing can be calculated and, if desired, optimized.

For verification, it is advisable to also record the corresponding gearing part and the center distance as a safeguard. Of course, we can measure or record these and other geometries as well. Whether a detected fault during an unplanned short downtime or as part of a repair in the workshop, you can count on HUEBER GEAR XY. We look forward to hearing from you.

Printouts of a measurement with HUEBER GEAR XY

All data could be generated from the undamaged tooth flank without any issues. The plot confirms the required flank form. The center distance was determined and confirmed by measuring the opposing gear and considering both profile shifts. The new parts can be manufactured precisely and true to the original.

With HUEBER GEAR XY, you gain the freedom to order your gearings.

Image 1 und 2 – defective gearing parts sent by the customer.

The parts were promptly measured, and after the customer received a quote, they were commissioned for remanufacturing.