As a byproduct or complement to the measurement of unknown gearing with HUEBER GEAR XY, we can, of course, also measure other components such as housings according to your specifications.

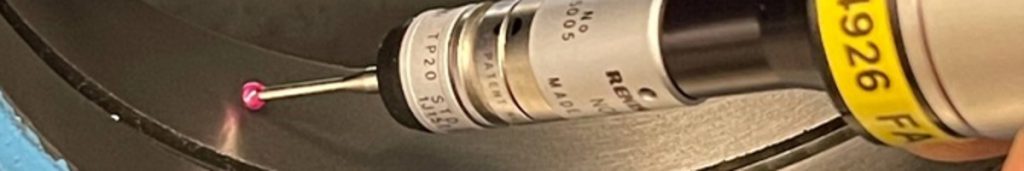

At our facility (up to 2 tons) or at your location, we can quickly and flexibly measure your components.

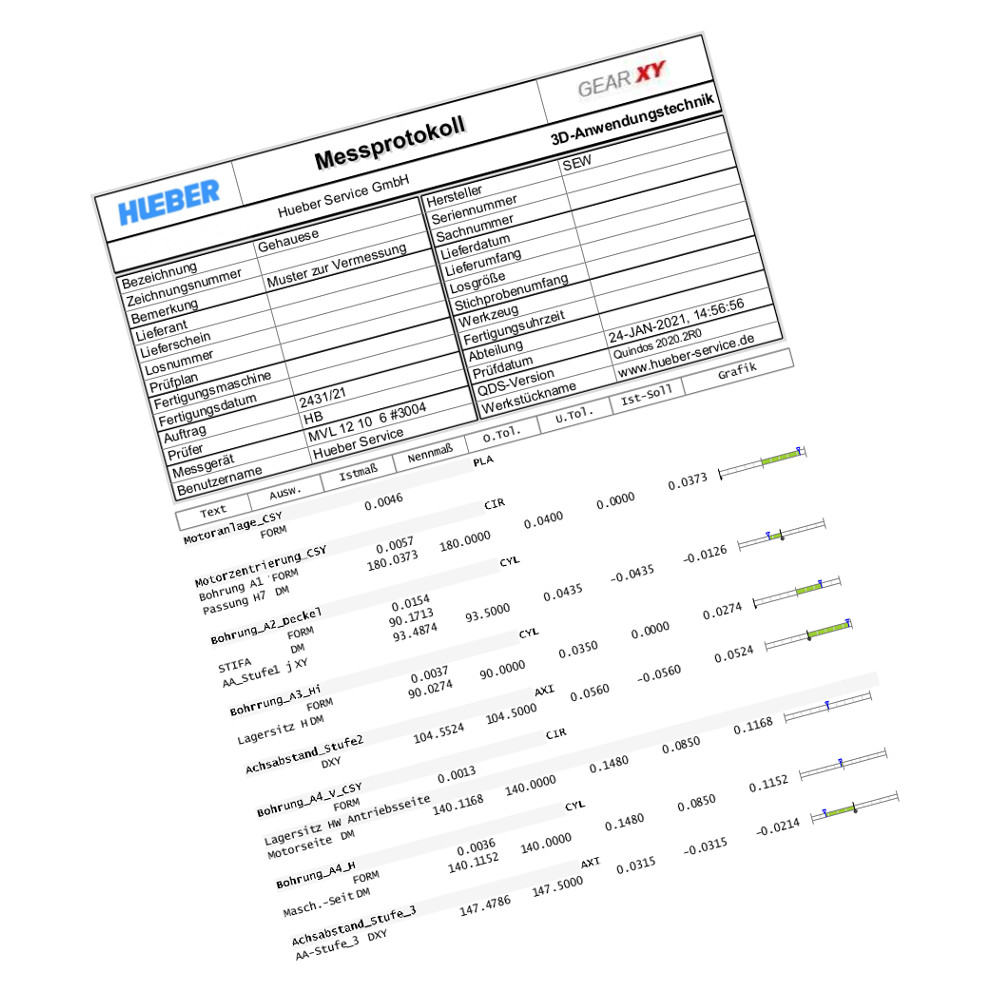

You provide us with the dimensions to be measured with tolerances, and after the measurement, we create a protocol with the measured values and indicate the deviations from your specifications accordingly.

The measurement of the axial distances alongside the housing bores is also useful as a check/verification of gearing data determined by HUEBER GEAR XY.

Measurement of the mounting surface and centering on the motor mount

Measurement of bearing seats, shafts, and axle positions on the housing

Result protocol for housing measurement

Here is an example of a contract measurement carried out directly on-site at the customer’s location.

Image 1:

After the housing measurement, the geometry of the old parts was measured. Using GEARXY and subsequent calculation, an optimal gear geometry tailored to the housing was generated.

Image 2:

The OEM of the gearbox no longer exists. After over 40 years of operation, it was decided to geometrically inspect and record both the housing and the gear parts due to emerging running noises.

Image 3:

After an in-house overhaul, a gear stage with new original parts failed again after two years. Before reassembly, the housing was checked for possible settlements and resulting axis errors.